CASINO PROJECT WESTERN COPPER & GOLD COMPANY located in CANADA – OXIDE PLANT MODEL

PATFIO is developing a simulation model for the OXIDE PLANT associated with the CASINO Project, which is owned by WESTERN COPPER & GOLD Company located in CANADA. This initiative is grounded in the feasibility studies that have been carried out for the CASINO project.

PROCESS DESCRIPTION:

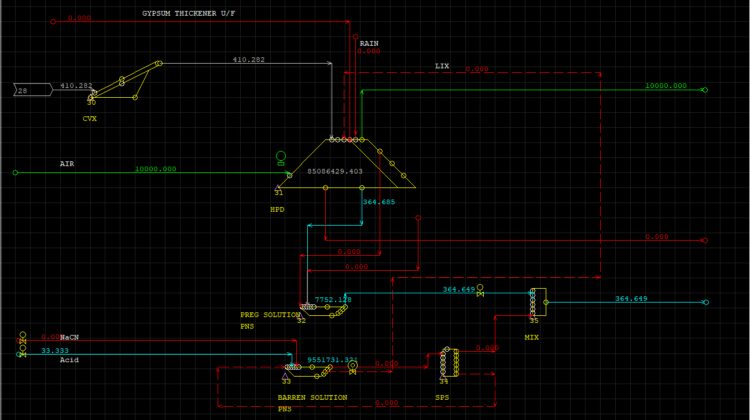

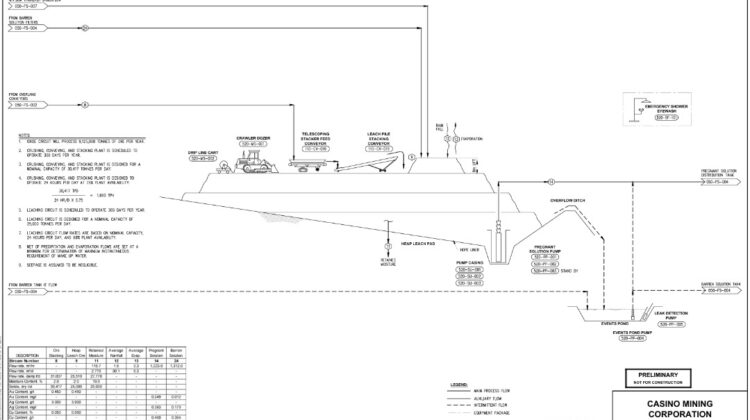

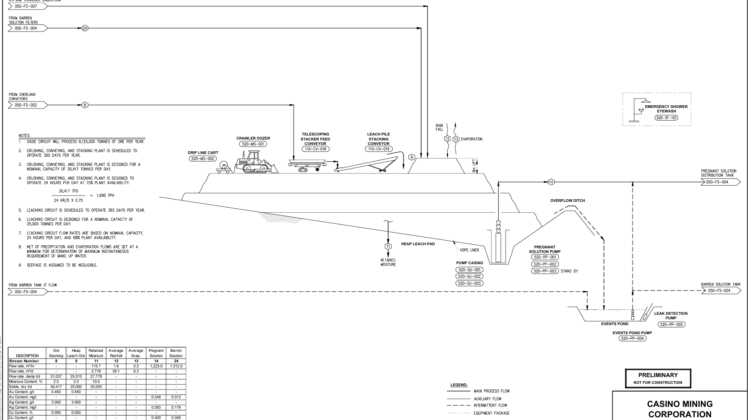

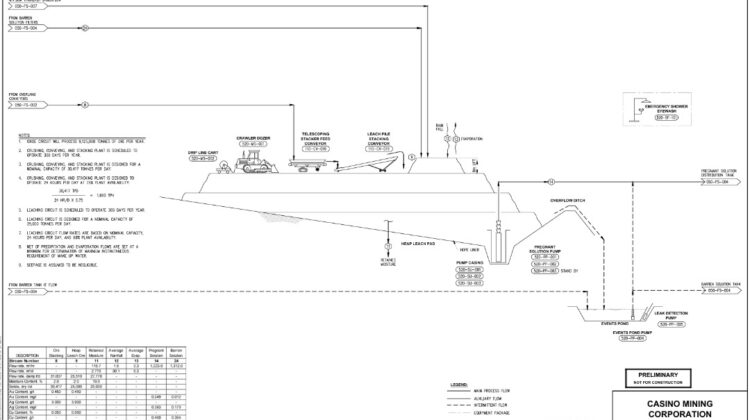

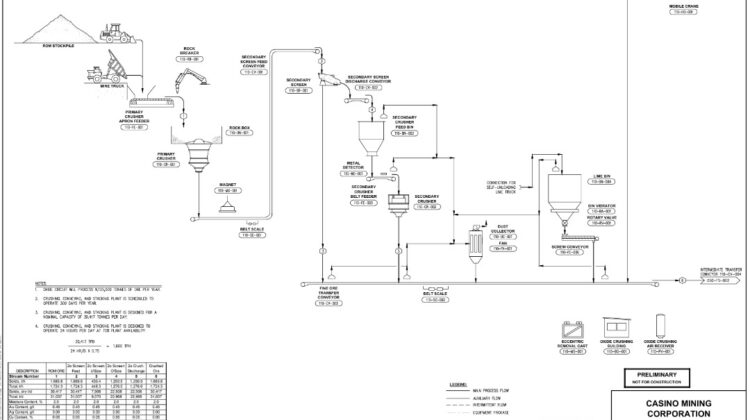

The ore undergoes crushing through both Primary and Secondary Crushers before being piled onto a heap leach pad. A barren process solution is then applied to the mineralized material. To reduce evaporation losses, the solution is delivered via drip emitters. Once the primary leach cycle for a mineralized material lot is finished, the application of the solution ceases, and a new layer of mineralized material is added on top of the existing one.

The application of the leach solution will then continue. This layering and leaching process can be repeated for up to eight layers of mineralized material on the leach pad. After the final leach cycle is completed on the last layer, the heaps of mineralized material will be washed with fresh water to extract any remaining gold and to cleanse the residue. The pregnant solution that drains from the heaps will be collected through a network of pipes installed within the overliner material, directing it to the in-heap collection area.

From this collection area, the pregnant solution will be pumped out using horizontal, centrifugal pumps designed for pregnant solutions. The discharge pipes from these pumps will converge into a single pipeline leading to the carbon-in-column (CIC)/SART circuit for the recovery of gold and copper.

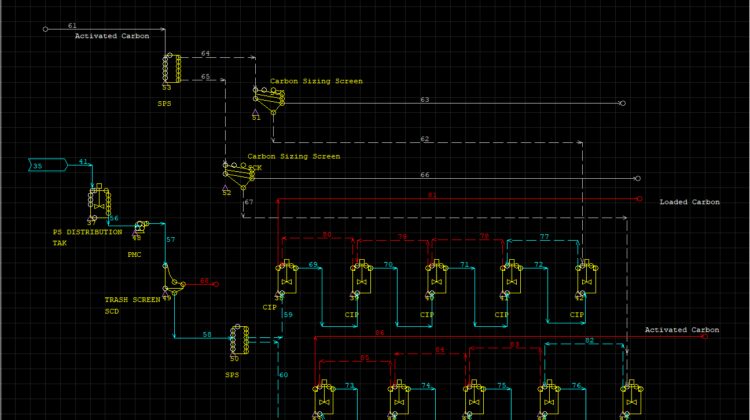

The steps involved in recovering gold and silver through the carbon adsorption method include:

– loading gold and silver onto activated carbon within the CIC circuit;

– performing acid washing of the carbon to eliminate water scale and acid-soluble copper;

– conducting cold stripping of the carbon (elution) to extract copper;

– stripping gold and silver from the carbon using a hot caustic solution;

– electrowinning gold and silver from the stripping solution, resulting in precious metal sludge.