Welcome to the Minerals Process Simulation course.

This course equips students with practical skills and knowledge of mineral process simulation technology. Mineral simulation technology is fast becoming more and more consolidated in the day-to-day business of the process operation, for a wide range of applications – from circuit diagnostics, plant design and equipment design, optimization, plant economics, mass balance, heat balance to operator training.

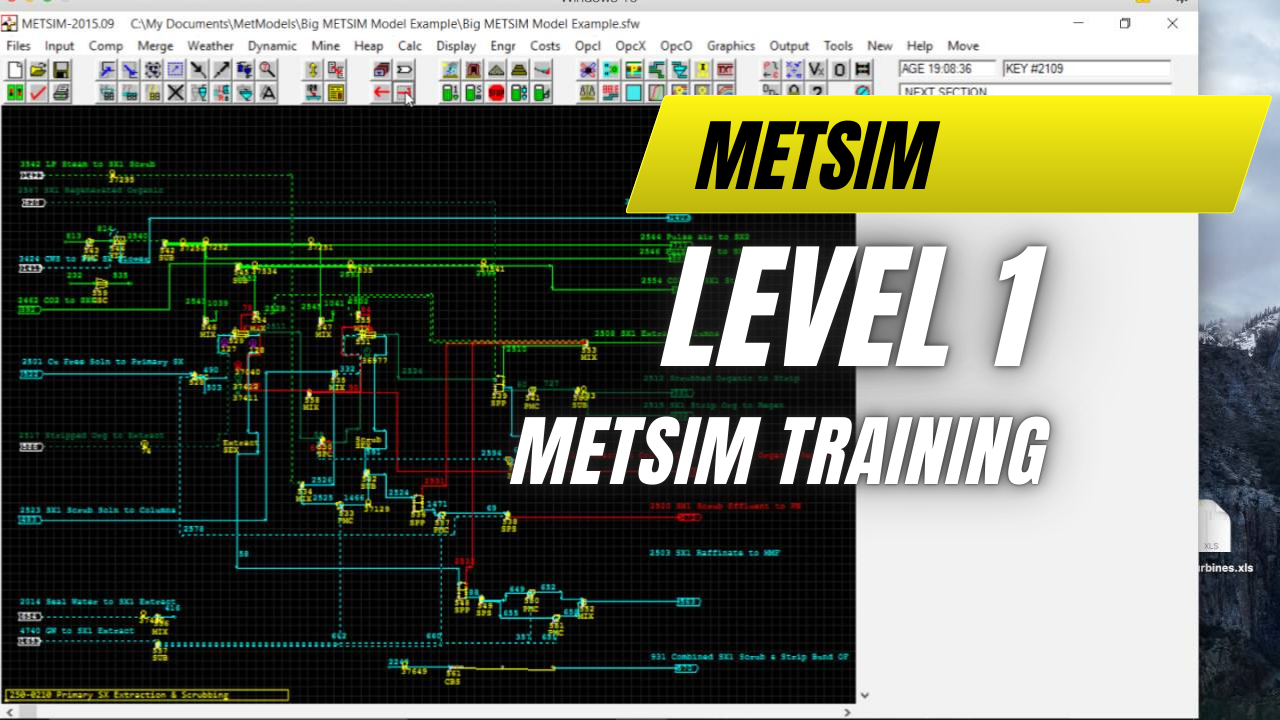

The use of simulation tools in real cases in the minerals industry can bring immediate benefits with high rates of return of investments involved. In addition to the theoretical approach, practical exercises are done during the course using one of the best Mineral simulation software called METSIM.

METSIM provides an interactive, fast and accurate means of solving costing, heat balance and material balance problems in a vast number of applications.

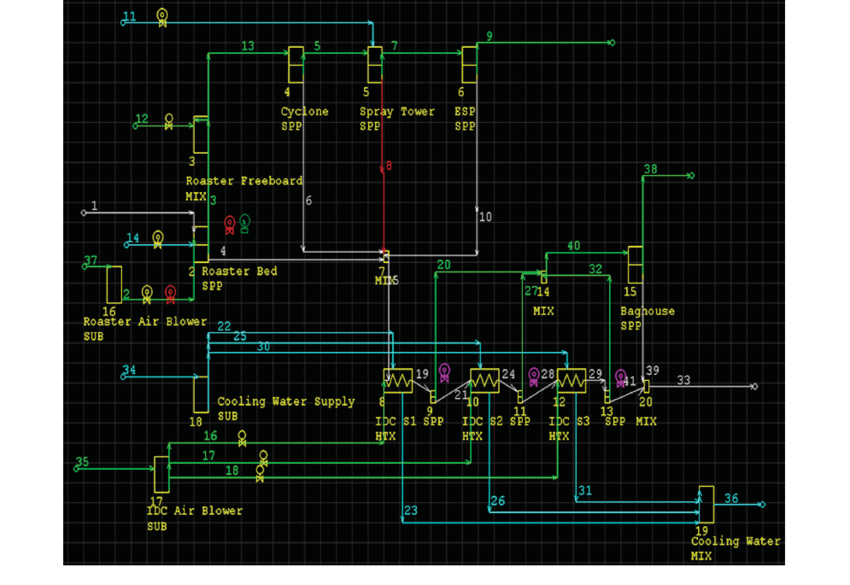

The software is used by many companies throughout the world to design, simulate and control operations from mine to tailings and everything in between. At its absolute simplest, METSIM software can be used to create a process flowsheet. The modules in METSIM covers mass and energy balances for either steady-state or dynamic simulations of mine, stockpile, heap leach, material handling, comminution, beneficiation, hydrometallurgy, pyrometallurgy, gas and steam handling, and tailings management processes.

Let’s talk about Features of METSIM that you will learn about:

METSIM has ability to make accurate calculations and algorithms through its simple-to-use interface which offers users platform for model creation. The modules in METSIM and its features make it an invaluable tool for de-bottlenecking and optimization tasks.

The first feature is Mass balancing based on design criteria which includes:

- Detailed equipment sizing and equipment lists;

- Steady-state simulation: mass and energy balancing;

- Parameterization to simulate existing/operating plants and;

- Dynamic simulation for time-varying parameters.

The second feature is Flowsheeting which includes:

- Easy to add new unit operations;

- Unlimited number of unit operations and flow streams;

- Flow-sheet and dynamic graphics;

- Capable of calculating single, multiple or all unit operations;

- Robust proprietary flowsheet convergence algorithm;

- Full graphical interface.

The 3rd Classical feature in METSIM is Chemistry, METSIM has an ……:

- Extensive thermodynamic database;

- Chemical kinetics and phase equilibria;

- And Eight solid, liquid, molten, and gas phases.

METSIM has also Process controls for:

- Feedback, feed forward, pH and PID controllers;

- Logic/expert systems;

- User-defined equations and algorithms.

METSIM is has high Compatibility, the software can link with Excel spreadsheets for Data exchanged making it simple for users to collect data from simulation models.

If you enroll in this course you won’t miss the hand-on appreciation of using METSIM simulator as well as understanding the best practices of performing successful metallurgical simulation studies.

If you are new to modeling and simulation in metallurgical operations, don’t worry anymore, this course first introduces you to the basics of mineral process simulation followed by a series of step-by-step practical demonstrations. Students are strongly encouraged to follow through the demonstrations and repeat the practicals on their own computers.

The course is basically divided into two parts, the 1st part is Introduction Theory and the 2nd part is Practical sessions. Part 1 is for students to;

- Understanding simulation technology in metallurgical processes.

- Industrial application of metallurgical process simulators.

- Simulators as a Strategic management tool.

- Understanding Steady State and Dynamic modeling.

- Methodology of performing successful simulation studies.

Part 2 is for students to have step-by-step guidelines to Practicals using METSIM for them to model and simulate any real world scenario. Part 2 includes the….

- Navigating METSIM simulator

- How to build a Simple steady state Model in METSIM

- How to configure feedback & feed-forward mechanisms in METSIM using an Agglomerator model.

- How to create Dynamic Models and also

- Analyzing Plant Economics using METSIM.

This course is ideal for students and professionals passionate about the Mining and Minerals industry including:

- Metallurgical engineering students.

- Chemical Processing Engineering students.

- Metallurgy students

- Research & Development professionals.

- Metallurgical consultants.

Getting Started

Let's learn by doing!

To proceed well with the course please follow the step by step instructions in the Practicals handbook. I encourage students to reproduce the practicals on their own computers for hands-on appreciation of the software.

Please note, download all materials in in the LEVEL-2-Training-Supporting-Materials (2) zip folder. (Password is PATFIO)

Section 1: What is Modeling & Simulation Technology?

Section 2: Exploring METSIM UI

Section 3: Simple Model Set-up (SUMP Model)

Build your first model

Section 4: Agglomerator Modeling

Section 5: Data handling (METSIM & EXCEL)

Section 6 - Feedback & Feedforward Control in METSIM

Section 7 - Modeling Dynamic models in METSIM

This is an extract from LEVEL 2 METSIM training course for trainees to appreciate how all the basic concepts will be applied to solve a complete flowsheet.

Section 8 - Analysing Metalurgical Plant Economics in METSIM

Hello!

PATFIO noticed that the Training Handbook attached on LEVEL 1 was incomplete, please note that a new PATFIO TRAINING HANDBOOK has been attached as the Materials of the Training Program. The handbook has all the step by step procedures for all practicals performed in the pre-recorded videos.

Kind regards.

PATRICK C.